Technical strength

1.The implementation of 6S management

Create a clean and orderly working environment, Provided the high quality and reliable products.

2. The production process control

1. The production process control

Turbine wheel material K418 Nickel -based superalloy. This alloy under 900 ℃ has good comprehensive performance , good casting performance and stability

Casting Compressor wheel material is C355 that is made of aluminum alloy , uses the low pressure casting process ; Milling compressor wheel will be done according to the customer's choice, with 7075 or 2618 materials.

Turbine housing material is Nodular Cast Iron,it has good heat intensity. Meantime we can supply mid-Si-Mo ductile iron turbine housing according to customer’s requirement. That material is better heat resistance.

Compressor housing :Material is ZL101, it has good mechanical properties and good casting properties.

Bearing housing Material is HT250, it has good mechanical strength

2. Operation standard

Specification of design and development process, perfect the file management system.Production site by using the combined work instruction of graphic files, it is convenient for operators to understand and comply with them.

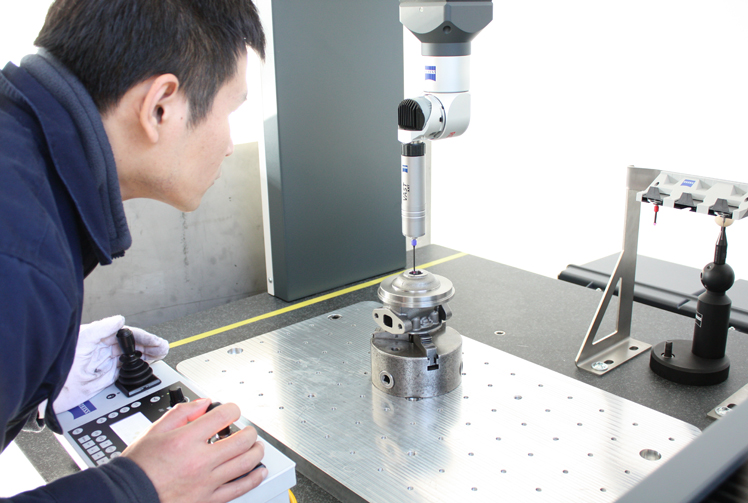

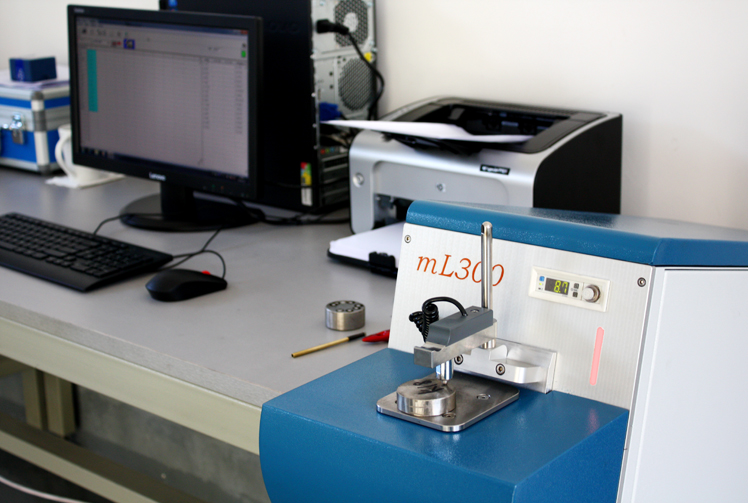

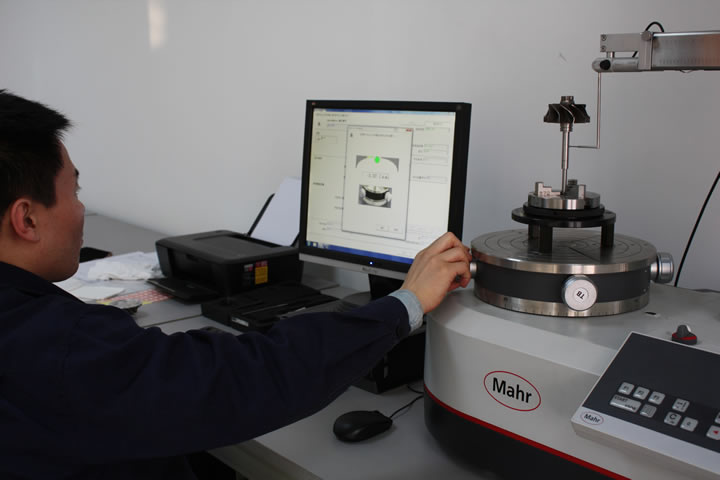

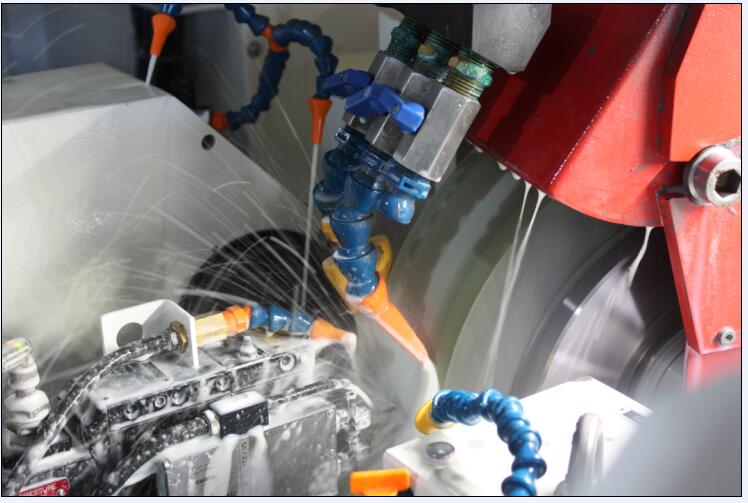

3、 Professional equipment

Housing batch cleaning ,Equipment cleaning line to replace manual cleaning, to better ensure the consistency of the quality of cleaning and improved the speed.Highly Machining precision, batch high speed machining.After assembling cartridge, cartridge will be done 100% dynamic balance test ,to ensure product stability in the working process.